We are pleased to mention that the team associated with M/s. Global India Technomed is having a rich experience of S.I.T.C. of Modular Operation Theatres ( Indian/ Imported) , M.G.P.S. ( Medical Gas Pipeline system), Oxygen Generator Plant from Oxymat Denmark with AMC , CAMC & Operational also and other hospital engineering services like Equipments, Operation Theatre Integration and telemedicine since more than two decades.

We are one of the leading suppliers/Authorized Distributor of Oxygen Generator Plants (Oxymat , Denmark) for hospital use. Our Vision is to offer Generator Plants based on the latest Technology available in the world for supply of high purity Oxygen to medical institutions, considering that the Oxygen so produced is as per International Standards for medical use and is of high purity up to 93% ± 3%

Our Principal Oxymat, Denmark had over (60) sixty installations of Oxygen Generator plants of various capacities all over India and Nepal. Our installations range is spread all over India from Leh , Aizawl, J&K, Ghouwati, Bangalore, U.P., Delhi, Uttar Pradesh. Some of our esteemed clients include the Indian Army who has installed our Oxygen Generator Plants at Assam, West Bengal and several other places. You will be pleased to know, because of our very sound technical support, some of the plants installed even in the early 1990’s are still working without any problems.

Our Oxygen Generators are also equipped with High Definition Colored Touch screen which displays real time trending, curves of O2 pressure as well as O2 Flow.

Global India Technomed also offers wide range of High Pressure Booster (Oxygen Compressors) to fill up Oxygen Cylinders at 140 bars to 160 bars also. The filled cylinders can be transported to that part of the hospital or to the nearby dispensary/ hospital where the consumption of Oxygen is less.

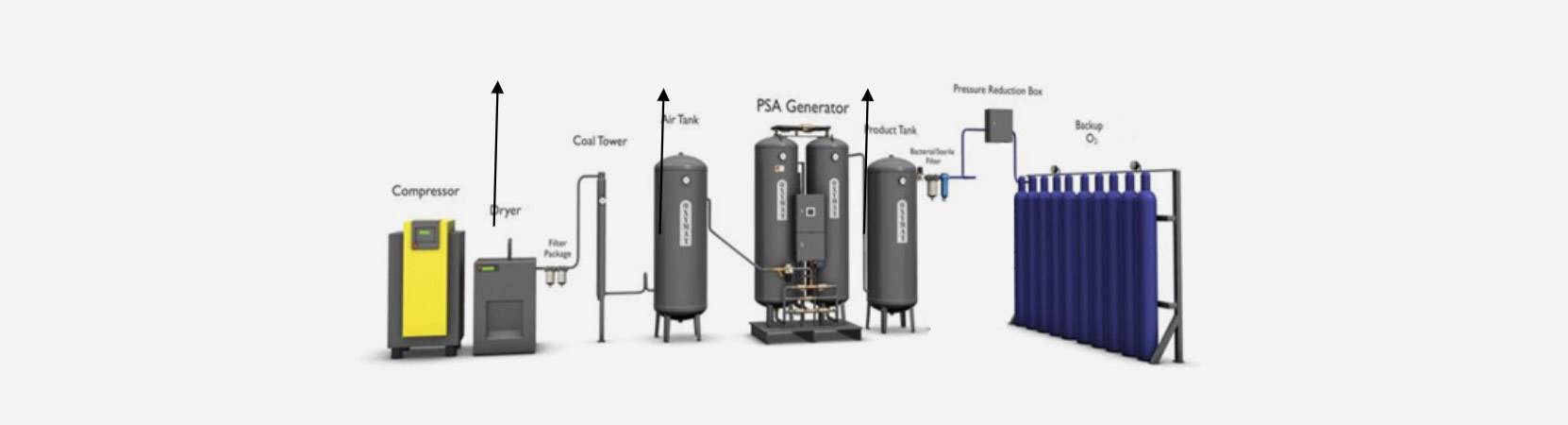

1. Compressor: (It shall be supplied from our stock as most of the reputed manufacturers are in India such as CPT,RIX,ICL, Kaeser Germany etc. etc.)

The produced compressed air is fed to the Oxygen Generator Module. (Imported)

Designed for a 24/7 duty profile. With energy-saving motor to minimize the energy costs.

2. Air Treatment Line: (Indian)

Refrigeration dryer which ensures quality, dry compressed air as per ISO 8573-1.Air filters providing clean oil-free compressed air with minimal pressure drop. Condensate drains protecting filters and ensuring minimal air loss.

3. Air Receiver: (INDIAN)

4. Medical Oxygen Generator:(Imported)

Providing medical oxygen in compliance with European Pharmacopeia and USP monograph Air filter providing clean oil-free compressed air with minimal pressure drop. Each Pressure vessel of Oxygen generator Module T1 & T2 tank must be certified for dynamic load, delta p 7bar for 2 million pressure cycles for the safety & reliability.

Inlet air dew point sensor shall be incorporated in the Pressure vessels ( T1& t2 ) to protect molecular sieve from high level of moisture during running operation.

5. Display Unit: (Colour)

Based on a robust PLC architecture and a high definition color touch screen panel.

6. Oxygen Tank: Used to store oxygen

7. High Pressure Booster (Optional): Used to fill up oxygen in cylinder so that the hospital has extra oxygen in case of emergency.