We are pleased to mention that the team associated with M/s. Global India Technomed is having a rich experience of S.I.T.C. of Modular Operation Theatres ( Indian/ Imported), M.G.P.S. ( Medical Gas Pipeline system), Oxygen Generator Plant from Oxymat Denmark with AMC, CAMC & Operational also and other hospital engineering services like Equipments, Operation Theatre Integration and telemedicine since more than two decades This is a brief introduction on Medical Gas Pipeline Systems. Medical Gas Pipeline system is the backbone of any hospital. It ensures that all the departments (OT, ICU etc) get the required gases in a timely and orderly fashion. Following are the components required to fulfill the same.

The materials are accompanied by the following certificates:

1. Certificate ISO 9001/2000 for "Design, production, quality control and installation of medical gas and vacuum supply systems and hospital equipment".

2. Certificate ISO EN 13485/2003 for "Design, production, quality control and installation of medical gas and vacuum supply systems and hospital equipment".

Terminal Gas Outlets

Medical compressed gases and vacuum outlets are suitable for external or internal wall mounting, for bed head unit and ceiling pendant installation. Two-part outlets are composed of the base part and the finishing part according to EN ISO 7396-1 & 2, EN ISO 9170-1 & 2 standards. Two-part Outlets for O2 - N2O - Air- Vacuum - Compressed Air according to ISO 7396-1, 2 Outlets are installed at the final delivery points in a medical gas pipeline system. They are used to supply the various gases using special quick-action connection fittings. The two-part outlets are composed of the base part and the finishing part.

Medical Grade Copper Pipes

Copper Pipes used are solid drawn, seamless, deoxidized, non arsenical, half hard, tempered and degreased, manufactured as per BS EN 1057, BS 2871 part I, table-X of 1971 and chemical composition as per BS-6017 of 1981, Table 2 and Cu-DHP. Manufacture’s Test Certificate of copper pipes for physical properties and chemical composition are provided. Further, the pipes are tested by a reputed third party i.e. Lloyds

Register Services Pipe sizes will be used as:

76 mm OD X 1.5 mm thk 22 mm OD X 0.9 mm thk 54 mm OD X 1.2 mm thk 15 mm OD X 0.9 mm thk

12 mm OD X 0.7 mm thk 28 mm OD X 0.9 mm thk 42 mm OD X 1.2 mm thk

Medical Compressed Aie Plant

Air compressor system with three or more compressors, two or more reservoirs, one duplex conditioning system (absorption dryers, pre-filters, activated charcoal filters, particle filters and dew point alarm), emergency inlet point and electronic control panel is according to EN ISO 7396-1 and HTM 02-01. A wide range of capacities from 10m3/h to 1.000m3/h are available to satisfy any request. The fully automatic medical compressed air plant provides a reliable and constant air supply, in predefined pressure level, without the transport and management cost associated with heavy gas cylinders. The plant is designed to operate at a maximum of 10bar. A wide range of models are available to satisfy all types of installations.

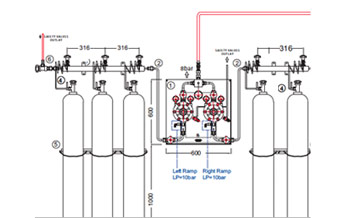

Manifold System

The automatic change over decompression unit is designed to supply medical gas (oxygen- nitrous oxide-air-nitrogen-carbon dioxide) of any type of medical gas network, where continuity of supply is essential and where the pipeline is supplied from manifold high pressure gas cylinders. This product complies with all current safety regulations and laws and is designed and tested to guarantee safety operation. Automatic central manifold system for medical gases (O2, N2O, Air, N2, CO2) with pressure reducers, high pressure shut-off valves, automatic change over unit, analogue sensors, cylinder ramps, flexible connections, pigtails, cylinder holders and emergency inlet point is according to EN ISO 7396-1 and HTM 02-01.

Control Panel

The automatic change over decompression unit is designed to supply medical gas (oxygen- nitrous oxide-air-nitrogen-carbon dioxide) of any type of medical gas network, where continuity of supply is essential and where the pipeline is supplied from manifold high pressure gas cylinders. This product complies with all current safety regulations and laws and is designed and tested to guarantee safety operation. Automatic central manifold system for medical gases (O2, N2O, Air, N2, CO2) with pressure reducers, high pressure shut-off valves, automatic change over unit, analogue sensors, cylinder ramps, flexible connections, pigtails, cylinder holders and emergency inlet point is according to EN ISO 7396-1 and HTM 02-01.

Lockable Line Valve

The ball valves GS CIM312 are certified in accordance with the European standard EN 331:1998. They are approved in accordance with the European standard for gas appliances (90/396/EEC). Manufactured in accordance with EN 29000 - ISO 9000 are suitable for gas at low pressure. Available in the following sizes: 15mm, 22mm, 28mm, 35mm 42mm, 54mm and 76mm and 108mm sizes.

Area Valve Service Unit

The ASVU are fitted to all medical gas and vacuum services in a prominent and accessible position at the entry to wards, theatres, intensive care, recovery rooms, etc. The ASVU panel is conforming to EN ISO 7396-1, HTM 02-01 standards and contains in metal box shut-off valves, pressure gauges, gas-specific connectors and low-high pressure switches.

Area Alarm Unit

The medical gases alarm panels are designed to remote monitoring the signals of medical gases installations with uninterrupted visual and sound notice to technical service personnel according to EN ISO 7396-1 and HTM 02-01. Alarm panels: 5 gases floor local alarm panel Inputs: 5 analogue, 10 digital, two buttons (Silence-Test). Outputs: LCD 2×20,13 LED, Modbus, TCP/IP, Ethernet One station alarm panel Inputs: 5 analogue, 10 digital, two buttons (Silence-Test). Outputs: LCD 2×20, 13 LED, Modbus, TCP/IP, Ethernet Central alarm system for all gas stations (TCP/IP connection and WEB interface) Inputs: 15 analogue, 12 digital, KEYBOARD. Outputs: LCD 4×40, 21 LED, USB, Ethernet, 9 SPDT relays Centralized station for all alarm panels Inputs: 100 stations, interface touch panel PC or standard PC

Bed Head Units

Bed head units have been created for grouping all the necessary electrical, lighting, data, communications equipment and medical gases services and are designed to serve: Normal hospital care, intensive care areas, special care areas (reanimation, geriatric, coronary, etc.), old people home. All models of B.H.U. are constituted of extruded aluminum profiles, stove enameled, having different components for power mains, low and extra low voltages and for medical gases.

Ceiling Pendant Arms

The ceiling pendants for special treatment rooms, is placed at the ceiling of these rooms, such as intensive care units and surgeries, above the patient bed or above the surgical table. The ceiling pendant has been created for grouping all the necessary electrical, data and medical gases services, required for use in operating theaters in anesthetic, surgical rooms and intensive care areas. The ceiling mounted pendant system is manufactured totally of special extruded anodized aluminum profiles or stainless steel and is electrostatic painted to any desired color. The ceiling mounted pendant systems are produced according to ISO 11197, EN ISO 5359, ISO 7396-1, ISO 7396-2, ISO 9170-1, ISO 9170-2, EN 60601-1 standards and they are labeled CE0653 to guarantee a high level of safety for patients and personnel.

AGSS Plant

The suction and disposal to the environment of the redundant gases from the anesthetic equipment inside the operating theatres but also from the emitted anesthetic gases from patients in the stage of recovery, is being applied by using an automatic anesthetic gas scavenging disposal system (AGSS), through the AGSS outlets which are installed in various departments. The Anesthetic Gas Scavenging (AGS) system removes anesthetic gas mixtures from theatres and recovery areas, thereby protecting the medical staff from possible long term health hazards. By virtue of its design, the new active disposal system can produce high levels of capture simply by connecting the terminal unit to the anesthetic breathing circuit via a receiver unit, thereby removing the majority of "pollution" at source.

Ward Vacuum Unit

High flow suction regulator. (Ward Vacuum Unit) High stability and accuracy. Materials: body in ABS-PC, vacuum gauge cover in PC, O-rings in NBR and silicone, pneumatic mechanism in POM, inlet thread connection in chromed plated brass. Fast ON/OFF switch. Water trap (made in polycarbonate with safety valve and particles filter) or hydrophobic bacterial and virus filter. Range: 0-100 kPa – 0-750 mmHg. Precision: + 5% Flow: 90 L/min

Oxygen Flow Meter

Oxygen Flow Meter Available in a variety of calibrations Come standard with a 1/8" FNPT connection but will be custom configured upon request Available with a variety of adapters and accessories Color coded to specific gas MRI Options available Comes with a 1 year warranty.